The automotive post-paint inspection deck can be one of the highest densities of manual inspectors left in the automotive assembly plant. Inspecting for defects like dirt, scratches, solvent pops and analyzing orange peel can be a challenging manual task - especially since each inspector sees differently. The Inovision SMARTInspect system is a dynamic, moving-line automatic paint defect inspection system that is one of the smallest footprints in the market, a system you can install almost anywhere on your existing line. Using our software department's latest AI algorithms and patented image processing technology, we can meet throughput rates 80JPH and higher.

FEATURES

dynamic moving line installation

Most automated inspection systems require the vehicle to stop and then be scanned. The SMARTInspect system scans, identifies, and classifies defects as the vehicle moves through the scanning ring, at the plant line speed.

off the shelf hardware

We designed the most advanced defect detection system to use readily available, off-the-shelf hardware, reducing overall costs and lead times on spare parts. It also means your maintenance techs don't need specialized training on hardware used on our system.

Fully adjustable brackets

Each camera light pair is mounted on a fully adjustable bracket that is designed to lock securely to ensure cameras maintain their position through the model life cycle. When the next model change comes, cameras are easily adjusted or added without major costly upgrades. Once we set it, you can forget it.

edge to edge coverage

Most automated inspection systems require holes and gaps in the vehicle to be masked. Our software automatically masks these features, right to the edge of the surface. This means we provided the largest amount of surface coverage in the market today.

defect sizes are adjustable

Certain areas of the vehicle or parts require lower thresholds for defects you need to find. The system is capable of setting multiple defect size limits in multiple areas. We can customize this for what you need.

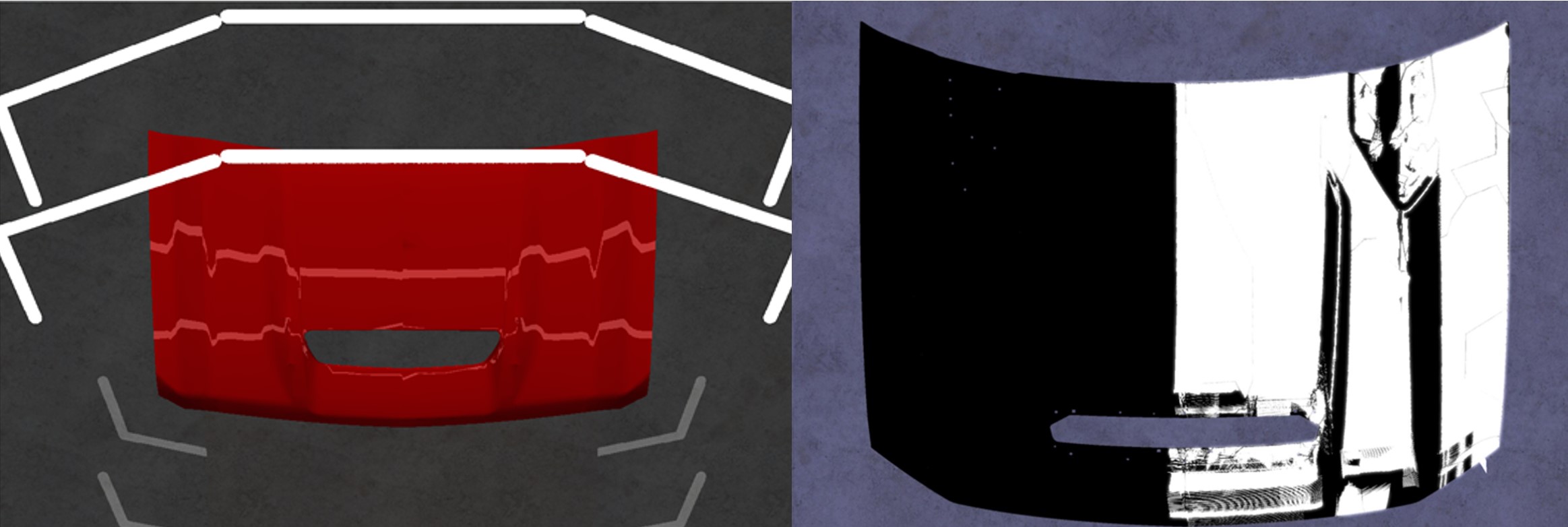

simulation based setup

Our simulation engineers are looking for coverage in the areas of detection, quality light reflections, and proper image resolution. Adjustments are made to the positioning until these goals are met.

The final output of the simulation is a coverage map showing all of the areas defects will be detected and the pixel per mm resolution for each surface of the vehicle.

HOW IT WORKS

Deflectometry

What is Deflectometry:

The measurement principle of deflectometry is based on the reflection of regular geometrical pattern on the object´s surface which is under inspection

Basically, when light passes off a reflective surface, any imperfections (i.e. perturbations) on the surface will be detected.

The SMARTInspect system is capable of detecting any kind of imperfection that causes a perturbation in the light reflection - as the vehicle passes under our system.

Imperfections over 0.2mm can cause light perturbations in our system.

multiple scans of the defect

Using high speed processors allow for high speed image acquisition, which therefore allows for defects to be detected multiple times as the reflection passes.

The multiple instances are clustered to increase the system accuracy.